Best Leak Detection Equipment for Industrial Use

In today’s demanding industrial environments, even small leaks can lead to downtime, compromised product quality, or dangerous working conditions. That’s why investing in the right leak detection equipment is critical for manufacturers who prioritize safety, quality, and profitability.

From advanced sensors to automated shutoff systems, leak detection has evolved dramatically. One standout example is the WeldSaver, a purpose-built device designed to protect robotic welding cells by detecting leaks in coolant lines and responding instantly. In this guide, we’ll explore what makes great leak detection systems, the core features of modern solutions like the WeldSaver, and why your facility can’t afford to ignore these technologies.

Why Leak Detection Matters in Industrial Settings

Leaks in industrial systems are more than just small nuisances. They can impact multiple areas of your operation:

Production Losses and Downtime

Leaks often require stopping machinery, diagnosing the problem, and repairing damaged components. This unplanned downtime disrupts schedules, leads to missed deadlines, and adds to operational costs.

Equipment Damage

If leaks go undetected, they can cause severe damage to high-value machines. For instance, coolant leaks in robotic welding setups can infiltrate electrical components, short-circuit systems, and destroy sensitive equipment.

Product Quality Concerns

In processes like robotic welding, inconsistent cooling due to leaks can result in weld defects such as weak joints or excess spatter. This ultimately means more scrap and costly rework.

Because of these risks, investing in specialized leak detection equipment is a must for forward-thinking manufacturers.

What Is Industrial Leak Detection Equipment?

Leak detection equipment refers to any tool or system designed to identify, locate, and often respond to leaks in industrial processes. Depending on the application, this equipment can vary widely:

- Pressure sensors: Detect drops in system pressure that might indicate a leak.

- Flow meters: Measure coolant or fluid flow, triggering alarms if readings fall outside preset limits.

- Ultrasonic sensors: Identify high-frequency sounds produced by leaks.

- Automated shutoff systems: Immediately stop fluid flow to prevent damage when a leak is detected.

A modern solution often combines several of these technologies into a single unit for complete protection—such as the WeldSaver, which integrates flow sensing, leak detection, and automated response in one.

Common Industrial Applications for Leak Detection

Leak detection systems are crucial in industries where fluid lines are vital to production. Typical applications include:

Robotic Welding Cells

These systems rely on water-cooled torches and cables to handle intense heat. Even a small leak can destroy torches, robots, or power sources.

Metal Fabrication and Cutting

Processes using plasma or laser cutters also use coolant circuits that must be monitored to maintain cutting quality.

The right leak detection equipment doesn’t just protect machines—it ensures the entire process remains safe, compliant, and profitable.

WeldSaver Overview: Specialized Leak Detection for Welding Systems

Among the best leak detection technologies on the market, the WeldSaver stands out for its advanced capabilities tailored specifically to robotic welding operations.

What Is the WeldSaver?

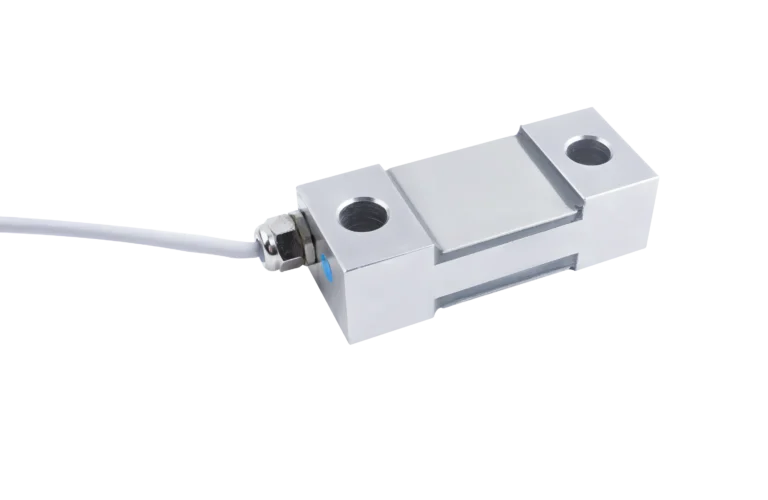

The WeldSaver is an integrated leak detection and coolant flow control device. It’s designed primarily for automated welding cells that rely on water cooling to protect torches and maintain weld quality.

Unlike basic flow sensors, the WeldSaver continuously monitors flow and temperature and reacts within milliseconds to any irregularities—shutting off coolant supply instantly to prevent further damage.

Key Features That Set WeldSaver Apart

Ultra-Fast Leak Detection

Where standard sensors might take several seconds—or rely on manual observation—the WeldSaver detects leaks in under 0.4 seconds. This immediate response prevents coolant from flooding expensive robotic systems.

Automatic Shutoff Capability

When it senses a leak, the WeldSaver immediately closes an integrated valve. This protects power supplies, cables, and sensitive components from catastrophic damage.

Dual Monitoring

It doesn’t just watch flow. The WeldSaver also monitors coolant temperature to ensure everything stays within operational parameters, providing an extra layer of protection.

Real-Time Alarms and Data Outputs

The system interfaces easily with PLCs and robotic controllers, sending digital signals that trigger alarms or stop production lines if needed.

Designed for Harsh Environments

Its robust build handles temperature fluctuations, electrical noise, and the tough conditions of welding shops, making it a reliable partner in demanding facilities.

Benefits of Using Leak Detection Equipment Like the WeldSaver

Reduced Maintenance Costs

By preventing leaks from damaging equipment, the WeldSaver saves thousands of dollars in potential repairs or component replacements.

Improved Weld Quality

Consistent coolant flow ensures stable torch temperatures, which means better bead consistency, reduced spatter, and fewer rejected parts.

Enhanced Safety

Instant leak detection keeps floors dry, reducing slip hazards and protecting workers from electrical risks associated with water around welding equipment.

Boosted Uptime

With reliable monitoring, you avoid unexpected shutdowns. Maintenance teams can focus on scheduled checks rather than emergency repairs.

Supports Predictive Maintenance

The data captured by the WeldSaver helps spot trends that indicate problems like gradual clogging or pump inefficiencies, enabling intervention before failure occurs.

Choosing the Right Leak Detection Equipment for Your Facility

When looking for leak detection solutions, consider these key factors:

- Speed of Response: Can it catch leaks before they cause damage?

- Integration: Will it connect easily with your existing control systems?

- Durability: Is it built to withstand your shop’s conditions, from high heat to electrical noise?

- Specific Design: General-purpose sensors work for many fluids, but welding systems need specialized tools like the WeldSaver for precise needs.

- Support and Documentation: Reliable manufacturers provide clear installation guides and support for integrating with automated cells.

Conclusion

Investing in the best leak detection equipment is crucial for any facility that relies on fluid-cooled processes. From protecting capital equipment to ensuring worker safety and maintaining consistent product quality, advanced systems like the WeldSaver represent a smart, future-focused approach to leak management.

For manufacturers looking for proven, high-performance solutions tailored to demanding industrial applications, Proteus Industries offers the WeldSaver along with a complete range of flow and leak detection technologies to keep operations running smoothly and safely.