What is the laser marking process?

Laser marking is the method involved with checking parts or workpieces utilizing laser innovation. A laser pillar hits the material, and energy makes a response and makes an extremely durable imprint. The speed, power, and focal point of the laser pillar on the part will prompt different laser processes. You can check to utilize laser etching, laser carving, laser strengthening, or laser removal.

Picking the right Laserowe znakowanie metali innovation and design is vital to stamp your parts effectively. To figure out what you want, you should initially characterize your application necessities. This incorporates data like:

your part material, size, and math

your accessible checking time

your creation interaction

Continue to peruse to figure out how these prerequisites will assist with deciding the laser framework, power, and interaction you want for laser checking.

1. All materials have an assimilation range

Frequencies discharged by most modern laser frameworks shouldn’t be visible to the unaided eye, so they’re difficult to envision. However, various materials respond diversely to various frequencies.

Every material has an exceptional structure that ingests specific frequencies and not others. Since lasers produce a solitary frequency, they’re exceptionally particular apparatuses for stamping quite certain materials. Various materials along these lines have different laser prerequisites.

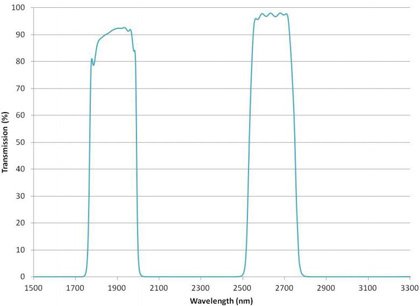

Contingent upon your material, you’ll either require a fiber laser framework or a CO2 laser framework.

2. Fiber and CO2 laser frameworks produce various frequencies

The different kinds of lasers radiate various frequencies because of their benefit medium — a part of the laser source. The material you’ll stamp will direct which sort of laser checking framework you want.

Fiber laser frameworks are best for stamping metals

Fiber laser frameworks are in some cases viewed as strong state lasers. They have a laser source that incorporates an optical fiber that contains an uncommon earth metal like ytterbium. They produce laser light on a frequency of roughly 1 micrometer (1064 nm). Most metals respond well with fiber laser stamping.

Gas-state laser frameworks are best for stamping natural materials

Gas-state laser frameworks have a laser source that incorporates gas. The most commonly known gas lasers are CO2 lasers. These laser checking frameworks can create laser light on frequencies that reach from 9 micrometers to 10.2 micrometers (9,000 — 12,000 nm). Most natural mixtures respond well to these frequencies. Yet, rather than fiber laser frameworks, metals respond ineffectively with these frequencies.

3. Every laser checking process offers various conceivable outcomes

Your application will direct which laser checking process you want. For instance, you might have to make exceptionally safe denotes that can’t be eradicated. Or on the other hand, you might have to fit the stamping system inside a particular process duration.

To pick a laser interaction, you should comprehend your requirements and your creation cycle.

The laser etching process is utilized to get safe marking example of laser etching

Laser etching imprints check somewhere down in the material by deteriorating part of the material into dust. For instance, laser etching machines can be utilized for VIN checking, which commonly requires profound markings that guarantee sturdiness and forestall misrepresentation. They can likewise be utilized for marks that should be impervious to forceful post medicines like shot blasting.

Laser carving is for fast and high-contrast marking example of laser scratching

Laser carving is normally utilized when the laser checking process should be essentially as quick as conceivable to incorporate a creation line. This innovation softens the material surface almost quickly, making high and low knocks on the outer layer of the material. This makes, for instance, high-contrast highly contrasting imprints.

Laser tempering is utilized to safeguard materials that should not be damaged example of laser toughening.

Laser toughening causes a synthetic change under the material surface. Nothing is crumbled, nothing is uprooted, and nothing softens. It’s one of the main answers for checking tempered steel, whose surface should stay unaffected by the imprint. Laser strengthening is likewise utilized for stylish applications like logos. Albeit more slow than other laser checking processes, it makes the most lovely surface completion.

Laser removal can be utilized to stamp by eliminating coatingsExample of laser removal

Laser removal makes an imprint by eliminating from the surface some different options from the material (ordinarily paint). Some portion of the paint can be taken out to stamp an identifier like a standardized identification. Laser removal is the same thing as laser cleaning. The main distinction is the application: the objective is to check, not perfect. In specific cases, laser removal is the quickest laser checking arrangement. For instance, eliminating paint is quicker than checking steel.