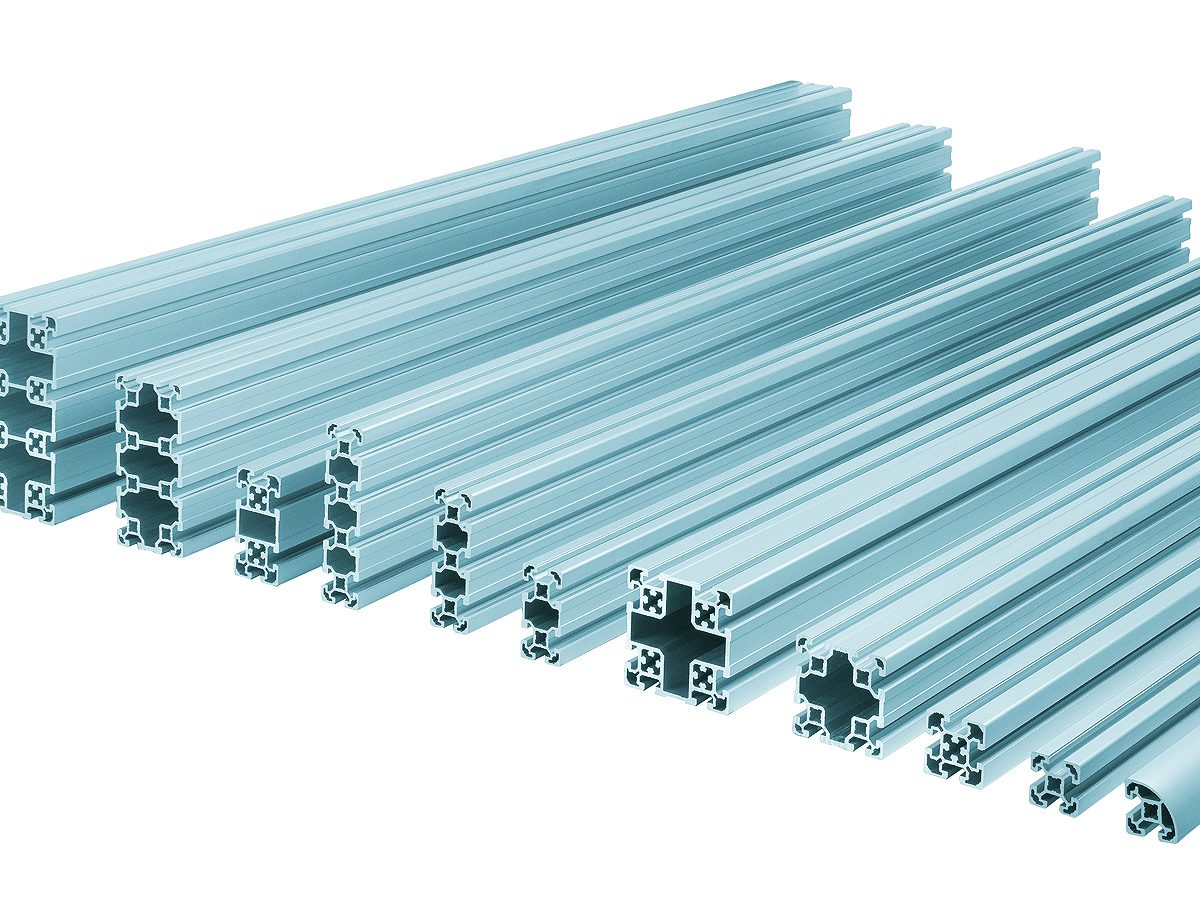

Aluminium Profile Manufacturers: Driving Industrial and Architectural Progress

Aluminium has become a cornerstone of innovation in industries ranging from construction to automotive. Among the key contributors to this growth are aluminium profile manufacturers, who produce versatile and durable components that meet diverse industry requirements. Complementing this, advanced finishing processes like aluminium anodizing further enhance the profiles’ functional and aesthetic value.

The Importance of Aluminium Profiles in Modern Applications

Aluminium profiles are extruded sections that offer a combination of strength, lightweight properties, and flexibility. These attributes make them indispensable for various applications in architecture, engineering, and industrial production. Aluminium profile manufacturers are pivotal in shaping these components to suit specific needs, creating products that are durable, efficient, and visually appealing.

Applications of Aluminium Profiles

The versatility of aluminium profiles allows their use across several sectors, including:

- Construction and Architecture: Aluminium profiles form the backbone of modern construction, used in windows, doors, facades, roofing systems, and curtain walls. Their sleek appearance and high durability make them a favorite for contemporary designs.

- Automotive and Transportation: In transportation, aluminium profiles contribute to lightweight vehicle designs that improve fuel efficiency and reduce emissions. Railways, buses, and aircraft also benefit from their use in structural and interior components.

- Electrical and Electronics: Aluminium’s excellent thermal conductivity makes profiles ideal for heat sinks, LED housings, and electronic enclosures.

- Furniture and Interior Design: Designers use aluminium profiles in furniture, modular systems, and interior partitions for their modern aesthetic and ease of customization.

- Industrial Machinery: Aluminium profiles are essential in manufacturing systems, conveyors, and modular machine frameworks due to their adaptability and strength.

Aluminium Profile Manufacturing Process

The manufacturing of aluminium profiles is a meticulous process that ensures precision and quality. Key steps include:

- Extrusion: Aluminium billets are heated and forced through a die to create profiles of the desired cross-section. The flexibility of this process allows for intricate and customized designs.

- Cutting and Shaping: After extrusion, the profiles are cut and shaped according to specific dimensions and requirements.

- Finishing: To enhance durability and appearance, aluminium profiles undergo surface treatments like aluminium anodizing, powder coating, or polishing.

Aluminium Anodizing: Enhancing Aluminium Profiles

Aluminium anodizing is a surface treatment process that significantly improves the properties of aluminium profiles. This electrochemical process forms a thick, protective oxide layer on the surface of the aluminium, providing several advantages:

- Corrosion Resistance: The anodized layer protects the aluminium profile from rust and environmental degradation, ensuring a longer lifespan.

- Enhanced Durability: Anodized aluminium profiles are highly resistant to wear and abrasion, making them suitable for high-traffic or heavy-duty applications.

- Aesthetic Appeal: The anodizing process allows for the incorporation of various colors, finishes, and textures, adding to the visual appeal of aluminium profiles.

- Environmentally Friendly: Aluminium anodizing is a sustainable process that produces no harmful by-products and is compatible with recycling efforts.

Advantages of Aluminium Profiles

The growing demand for products from aluminium profile manufacturers is driven by their numerous benefits:

- Lightweight Yet Strong: Aluminium profiles combine lightness with strength, making them easy to transport and install while maintaining structural integrity.

- Corrosion Resistance: Natural and treated aluminium surfaces, such as those with aluminium anodizing, resist rust and weathering.

- Customizability: Aluminium profiles can be extruded into a wide variety of shapes and sizes to suit unique project needs.

- Eco-Friendliness: Aluminium is recyclable, reducing environmental impact and aligning with global sustainability goals.

- Thermal Efficiency: Aluminium’s conductivity makes it ideal for applications requiring heat dissipation or energy efficiency.

The Role of Aluminium Profile Manufacturers in Industrial Growth

Aluminium profile manufacturers play a crucial role in meeting the growing demand for high-quality, customized aluminium solutions. By leveraging advanced technologies and materials, they ensure that the products they deliver meet the evolving requirements of various industries. From standard designs to bespoke solutions, these manufacturers are essential to the growth of industries reliant on aluminium profiles.

Market Trends in Aluminium Profile Manufacturing

The market for aluminium profiles is expanding rapidly due to increased urbanization, industrial development, and government initiatives promoting sustainable construction. Emerging trends include:

- Smart Cities and Green Building: Aluminium profiles are essential for energy-efficient building designs, including solar panel mounts and thermal insulation systems.

- Lightweight Transportation: As electric vehicles and fuel-efficient designs gain traction, lightweight aluminium profiles are increasingly used in vehicle frameworks and battery enclosures.

- Advanced Finishing Techniques: Processes like aluminium anodizing are becoming more sophisticated, offering enhanced durability and aesthetic options.

- Automation in Manufacturing: Automation technologies improve production efficiency and allow for precision in creating complex aluminium profiles.

Challenges Faced by Aluminium Profile Manufacturers

Despite the growing market, aluminium profile manufacturers face several challenges:

- Raw Material Costs: Fluctuating prices for aluminium and energy can affect production costs.

- Environmental Regulations: Stricter environmental standards necessitate the adoption of sustainable practices in production and finishing processes like aluminium anodizing.

- Global Competition: The global aluminium market is highly competitive, with manufacturers from China and other regions posing challenges.

- Technological Advancements: Keeping pace with innovations requires significant investment in research and development.

The Future of Aluminium Profiles

The future of aluminium profiles is bright, with advancements in technology and sustainability paving the way for growth. Key opportunities include:

- Sustainable Construction: With a focus on eco-friendly materials, aluminium profiles will play a critical role in green building projects and renewable energy infrastructure.

- Electric Vehicles (EVs): As the EV market grows, so will the demand for lightweight and durable aluminium components, particularly those enhanced through processes like aluminium anodizing.

- Global Exports: With competitive pricing and high-quality standards, Indian manufacturers are well-positioned to expand their share in the global aluminium profile market.

- Innovative Designs: The demand for customized, complex profiles will drive further innovation in extrusion and finishing techniques.

Conclusion

The contributions of aluminium profile manufacturers are instrumental in shaping modern industries and infrastructure. Their ability to produce durable, lightweight, and customizable profiles caters to the needs of various sectors, from construction to electronics. Processes like aluminium anodizing further enhance these profiles, offering improved durability, corrosion resistance, and aesthetic appeal.

As industries increasingly prioritize sustainability and innovation, the role of aluminium profiles is set to grow even further. By overcoming challenges and embracing new technologies, manufacturers will continue to lead the way in creating solutions that meet the demands of the future. Whether in smart cities, electric vehicles, or green buildings, aluminium profiles will remain a cornerstone of progress and development.